Full statement from Star Valley Meat Block regarding food bank meat confiscation

The following is a statement provided by Star Valley Meat Block, in response to the Afton Food Pantry being required to return meat donations from animals not processed at an approved USDA facility.

Thank you for the opportunity to talk about being USDA inspected and the recent events that have been brought to light on social media by the Afton Food Pantry. There have been accusations that we turned the Pantry in, and this is 100% NOT TRUE. There are a lot of people who are misinformed and misled, so we would like to provide Facts about the situation.

When we purchased the meat plant in 2017, we had a steep learning curve. At the time, Dana’s was operating as a Custom plant, as they had for +30-years, which means they could exclusively process meat for the livestock owner or the owner’s family. No custom processed meat could be sold to the public or retail customers. Animals must be sold alive, before processing, and with proper brand inspections. When someone in Wyoming purchases a new meat plant or opens one you go through an inspection process with the State, even if you are Custom plant. During

that process the State inspector makes sure you are set up to do a good job with Custom and wild game processing. Wild game processing is even less regulated in Wyoming. At the time of purchase, we had several improvements to make to the facility, like switching from a single bay wash sink to a double. It’s just part of the process of requiring plants to continuously improve even though the plant was already licensed. They also make you aware of the limitations of being a Custom processing plant. For example, when you are a Custom plant, your customers cannot resell

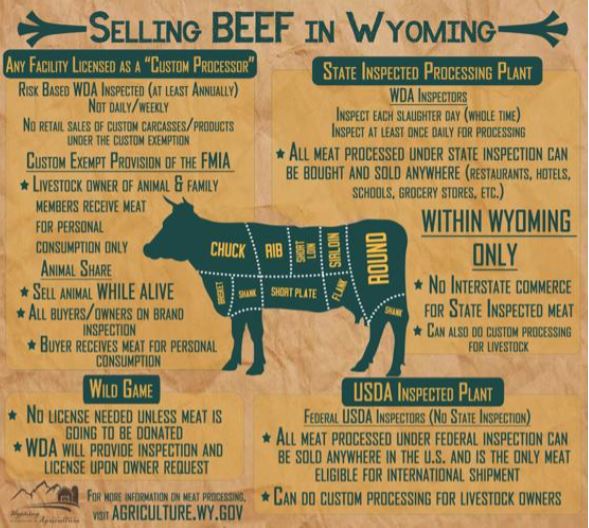

their meat or meat products or provide the meat to a food bank. This is made very clear from the get-go from the regional CHS (Consumer Health Services Specialist), Dru Haderlie. He does a good job communicating requirements. Figure 1. was published by the Wyoming Department of Agriculture. There is a ton of information on their website if people want to learn more about the regulation of meat processing in Wyoming. Go to Wyoming Dept. of Agriculture for a complete overview of the meat processing program.

Our first fair season was 2017 and it was a learning experience for us. The States Department of Agriculture and the Lincoln County Fair Board made it very clear that meat going to a food bank needed to be processed by a USDA plant. In fact, the Fair Board provides documentation to all buyers every year. They did this again this summer. After our 2017 learning experience, we started working with the local food banks that were frustrated about having to take donated meat to out-of-state meat processors because there was not a USDA meat plant in Western Wyoming. In coordination with them, and in conjunction with local elected and appointed officials, we started the process of determining what it would take to become USDA inspected to 1) help the local food banks and 2) help local growers be able to market their meat directly to consumers online, at farmers markets, or to stores and restaurants for resale. Our hope was this would also allow us to become a year-round business and keep our employees employed through the year. Beef prices were way down, and this offered many growers another avenue to increase revenue and diversify instead of just selling their beef through contracts or at auction and shipping to large feedlots and meat plants primarily located in the Midwest.

From 2018 to 2020 we worked hard to become USDA Inspected. The total investment to complete all requirements was well over $1M in addition to hundreds of hours. We made the leap. It was the right decision for us and the community. In 2020 we obtained our USDA inspection status. Not only did this require significant improvements to our facility but it also requires a full-time federal meat inspector to watch our operations and ensure safe meat products are produced. They ensure humane handling, sanitary conditions, that meat carcasses are cooled fast enough to prevent bacteria growth, continuous testing for bacteria, that offal is disposed of properly, and provide overall oversight of meat processing and cooked/smoked products to ensure no one gets sick. Extra focus is placed on oversight of smoked and cooked products that present additional food safety risks if not done properly. We had to change our operations and improve. We now have many local and regional USDA customers and help food banks locally and regionally. Not only are we ensuring products are safe for the community, but this also ensures protection for our USDA customers and food banks who are at risk when they sell or provide meat to the public. They are also working hard to ensure a good, quality and safe product for our community and their customers.

There have been recent events where someone harvested their beef on the farm, in the dirt, open to all environmental bacteria with no processes monitored such as sanitizing hands, knives, aprons (if any were used), to prevent E.coli and to ensure overall safety whatsoever. These carcasses were then taken on the back of pick-up trucks to restaurants in Jackson and potentially to food banks (as said in the recent food bank inspection report, “some meat had no origin of where it came from and had to be thrown out”). This isn’t right and people could get very sick. Whether uninspected meat goes to the high spenders at a Jackson restaurant or a local food bank; the consequences could be devastating.

Meat processing and slaughter are highly regulated because if they are not done correctly consumers can become very sick or die. The USDA requires a detailed HACCP, or Hazard Analysis Critical Control Point, plan to be developed that is a comprehensive management operating system that helps a facility ensure food safety by analyzing and controlling biological, chemical, and physical hazards throughout the food production process, from raw material procurement to consumption. The system is built on seven core principles: conducting a hazard analysis, determining critical control points (CCPs), establishing critical limits, monitoring CCPs, taking corrective actions, verifying the system, and documenting procedures and records. HACCP is essential for maintaining food safety and preventing foodborne illnesses. It was developed in the 60’s because of the same issues we are talking about now.

The more we have learned and grown, we understand why USDA inspection is important for meat supplied to a food bank. It ensures the safety of the underprivileged and underfunded when they need help. We don’t know why the local food bank decided they did not need to utilize a USDA inspected facility and the outcome is very unfortunate for everyone involved. This meat should not have been wasted and it’s not the State’s fault. We also don’t know why a processing facility would supply meat to a food bank if they were not USDA Inspected. The State makes it very clear this isn’t OK in many forums. As to the accusations that we are the party that turned the food bank in – completely, 100% not true. The food bank was not turned in. The State was doing inspections, like they do in every County, and they learned about the situation through the inspection. We have lived through many inspections and investigations. We were also questioned by the State when they found that we supplied one (1) lamb to the food bank that was not processed under USDA inspection, it was ultimately determined that the owner had donated it after being picked up from our facility and was not communicated to us at the time of processing. After reviewing the situation, it was found that our facility followed the correct procedures. Unfortunately, this meat had to go back to the donor also. We are learning from this and implemented additional communication steps to remind customers of donation requirements at the time of drop-off to ensure this does not happen again.

Meat processing plants are inspected by the state department of agriculture, brand inspection, and the USDA. Strict regulations also exist for offal and sewage disposal monitored by State and local municipalities. Part of the USDA inspection process is a review of these facilities procedures also.

The fact that uniformed people are making accusations about what happened and defaming us is unfortunate. We will keep taking the moral high road and improving and working with local and regional food banks; as well as military personnel/veterans, locals and our community. Over the last 8years we have donated over $50K to people in need and veterans. Showing our continued commitment to the local community in need, we held a fundraiser this summer right before the fair and raised over $800 that was given to the food bank to help with processing fees. Our employees volunteered on their own time. We donated the beef that was auctioned to raise the money. Unfortunately, this donation, like others and Grant funds, did not lead to any people benefiting due to its misuse.

We work hard every day to ensure that food safety is our number one priority. Those who know us know who we are and what we stand for – we make sure to do things right the first time and stand behind our word, product, ethic, and Team.

3 COMMENTS

Comments are closed.

I am fortunate to live in SV for the past five years. One of the businesses that I have had the opportunity to be a customer is Star Valley Meat Block. As a customer/ consumer / hunter I am proud to have Star Valley Meat Block in my community. And while I have never been to the Afton Food Pantry, I have heard many good things. I sense something (someone) outside of these two businesses was involved to create this drama. Neither The Block or the Pantry deserve this BS as they are both great contributors to our community. Hopefully this situation is resolved, and both businesses deserve our respect and support…