Remembering the Star Valley Cheese Factory: The legacy lives on

In 1951, Time magazine featured a small 30-man cheese factory in Thayne, Wyoming. The article from the Dec. 3 issue said: “From it come thousands of pounds of Swiss cheese which Star Valleyites think, with some reason, is the best made in the U.S.”

For “Star Valleyites” who remember that factory in Thayne and especially those who labored to make probably millions of pounds of Swiss, mozzarella, provolone and ricotta cheeses over some 56 years, the pride in the “best made in the U.S.” is earned.

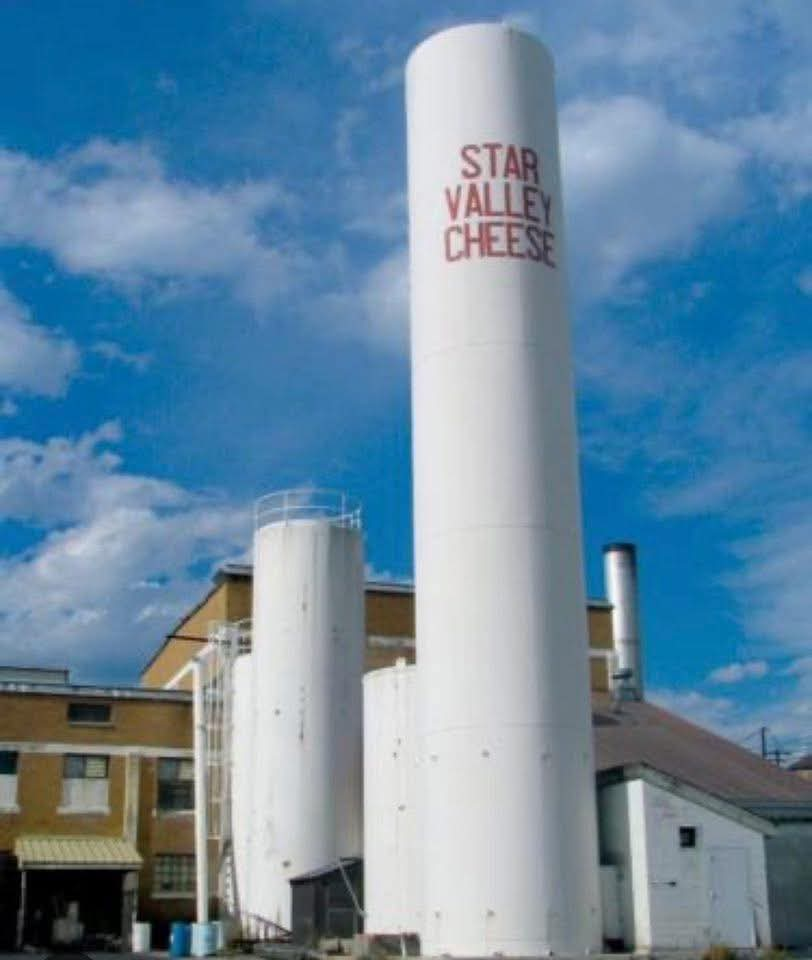

Today, 20 years after the Star Valley Cheese Factory — originally named the Star Valley Swiss Cheese Factory — closed in November 2005, those who marketed the cheese, stirred the vats, made the cultures and cleaned and maintained the machinery still remember the legacy.

“The cheese factory has been an icon there for a lot of years,” then-town councilman Don Aullman told the Casper Star-Tribune for its story on the closing of the factory, according to the Nov. 30, 2005, issue. “It’s a passing of sorts, a changing of the guard. … “Us people that have been here for all of our lives hate to see these changes, but that’s just what happens.”

Aullman, who died in 2014, also served as the mayor of Thayne. His cousin, Dale Aullman of the Box Lazy J. Ranch outside Thayne, has history with the cheese factory as a longtime employee in charge of maintaining the equipment for years. Now 76 years old, he joined with two other former employees of the Star Valley Cheese Factory to reminisce on what is the 20th anniversary of the closing of that Star Valley “icon.”

Some, like Dale Aullman, even remember the original owner and founder of the Star Valley Cheese Factory — Ernest Brog. Up until 1962, according to the Nov. 29, 1962, issue of the Star Valley Independent, Brog was a Swiss immigrant to the region who was known as the man “who has undoubtedly brought more fame to Star Valley than any other man.”

According to the Time magazine article, Brog arrived in this “star of all valleys” in 1923, having mastered the art of cheesemaking in Switzerland. Others like him had immigrated here, bringing expertise in dairy farming. Over time, Star Valley became known as “America’s Little Switzerland.”

The Time article related: “Brog taught valley farmers how to improve their herds and boost milk production, often bought equipment for them out of his own pocket, joined the Mormon Church [The Church of Jesus Christ of Latter-day Saints] to which most of them belong.”

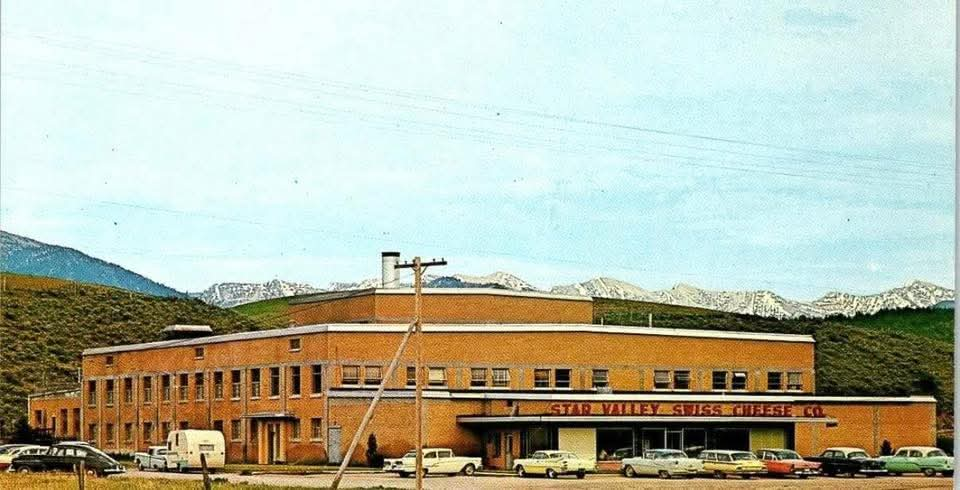

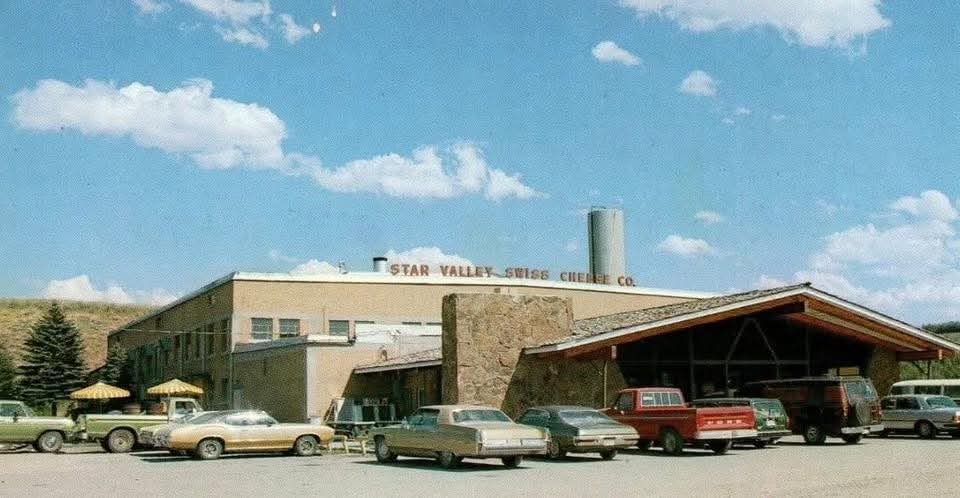

According to the Star Valley Historical Society, Brog opened the Star Valley Swiss Cheese Factory in Thayne on Jan. 1, 1949. The Thayne site, constructed in 1948, was one of several creameries in the valley, but Brog consolidated the business in Thayne. Originally just producing Swiss, the factory began processing the milk into Italian cheeses — mozzarella, provolone and ricotta, according to the Casper Star-Tribune article.

Over the years, the factory passed to other owners who kept the plant going until 2005 when the closing was brought on by dwindling diary producers in the region. The Star-Tribune recorded that at its closing, the plant had the capacity to produce up to 1.5 million pounds of cheese per month and shipped to markets across the United States and as far away as Hawaii. At one time, the plant received milk from some 30 milk producers in northern Lincoln County.

Aullman, in particular, remembers the Brog brothers, including later manager Frank Brog, Ernest’s son. “They were really nice people,” Aullman related.

The third-generation valley rancher was a young man in 1969 when he returned to Star Valley after a stint in the U.S. Army. Jobs were scarce here, but he was determined to come home to his roots. “I grew up here in the hills and the woods, and I just missed them. I’m not a city person.”

Hearing of an opening at the cheese factory, he applied and was hired by Frank Brog. His first responsibility was working with the whey powder for the ricotta and handling Swiss cheese blocks. A few years later, after the head of maintenance, Rony Suter, retired, Aullman took over and remained in that position until he retired in 2005. Along with a handful of others, Aullman was among those who closed and locked the doors that last time.

Speaking with SVI Media over the phone, he related how Ernest Brog used to come to the boiler rooms to “see how things were going. He was a pretty smart man. He always asked if I needed anything.”

Aullman chuckled recalling keeping the boilers running even when the coal got wet upon delivery. “I’d have to spend the night keeping the coal coming so things didn’t freeze up. You get down in the coal silos and break it up so they could feed into the boilers.”

He’d get home in the morning covered in black dust.

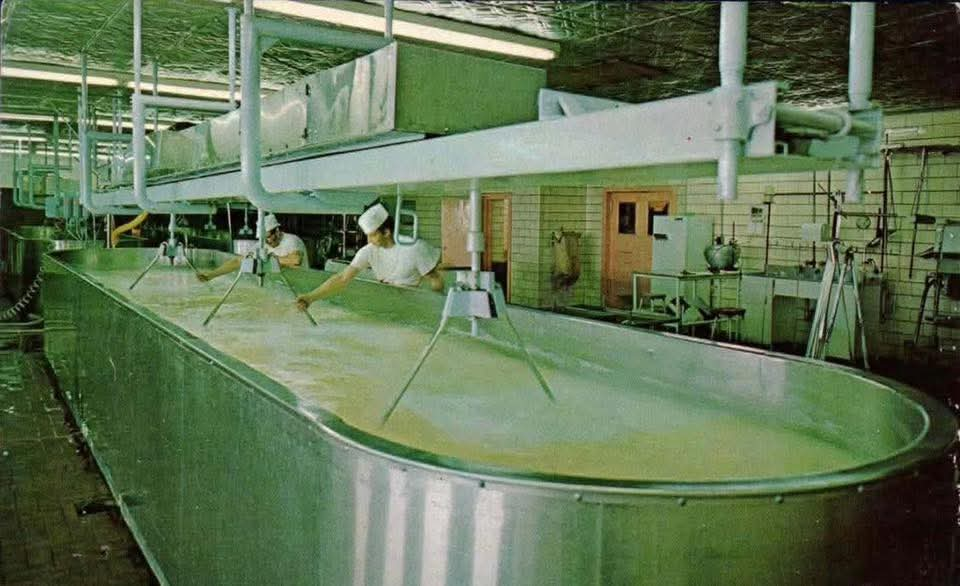

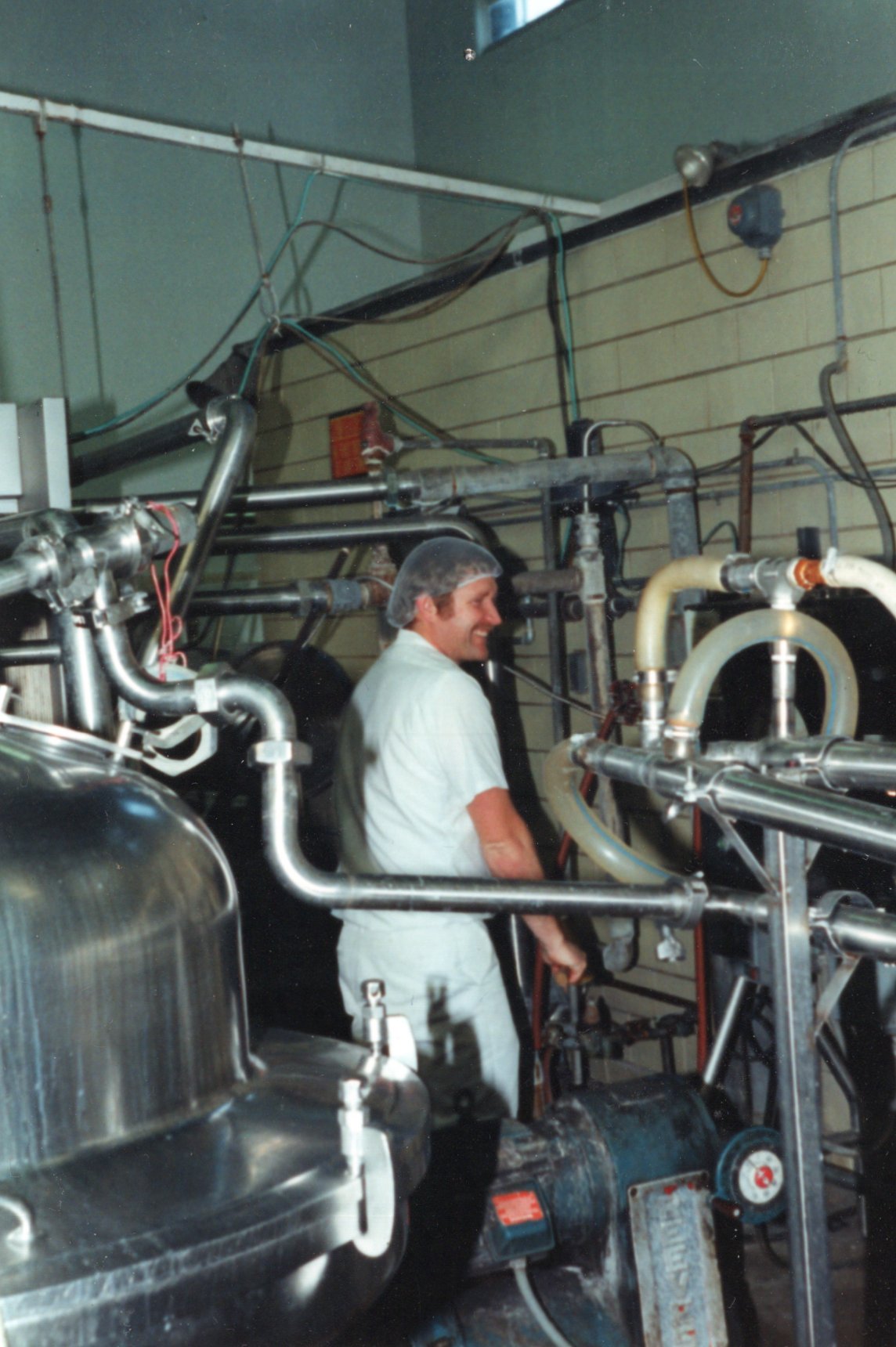

in preparation for delivery throughout the United States and as far

away as Hawaii. One former worker, Kory Turner, said they made any-

where from 12 to 14 vats daily and went through millions of pounds

of milk. COURTESY PHOTO

For Kory Turner, returning to work at the Star Valley Cheese Factory after a mission and college meant he could stay with his roots on family land homesteaded in what today is Turnerville. Now 63 years old, Turner was about 15 in 1977 when his father mentioned he could work at the cheese factory making cultures after school. The school bus would even drop off kids at the factory each afternoon. While other friends were moving sprinkler pipes, he was making $3.50 an hour at the cheese factory, working alongside two of his best friends.

Describing how to make the cultures, he explained it’s a bacterial culture used to make cheese. “I had to mix the big tanks full of powdered milk with other stuff mixed in. After I heated it to 190, it had to sit for 45 minutes. Then cool it down to 110. Then I went in and got these cans of bacteria that were frozen, 30 below zero. We wore gloves. We’d dump them into this big tank and stir for 10 minutes and then shut off the agitators. The temperature had to stay within 110 and 106 for the bacteria to grow. That had to sit for six hours.

“In the morning, the early shift would come and breathe the starter,” Turner added, explaining that the culture would then be cooled. “That would stop the growth of bacteria. Starter is yeast for cheese.”

After returning to the valley as an adult, he started where he left off and made it his career. There’s no way to calculate how much cheese he made, but each vat had 42,000 pounds of milk. “We made anywhere from 12 to 14 a day. We went through millions of pounds of milk.”

COURTESY PHOTO

He vividly recalls making that last vat of cheese with Joshua Floud in November 2005. “We had to use up all the milk. They’d asked us to stay so the milk wouldn’t spoil. The last vat was half a vat.”

Turner laughed when asked for a fun memory. When he worked there in his youth with his friends, it was their job to clean all the equipment with three high pressure hoses that could shoot jets of water 30 to 40 feet. “We had the biggest water fights we’d ever seen. From one room to another. Oh man! But we got our work done. We had a lot of fun. Everybody was wet.”

To this day, Turner takes pride in being part of the cheese factory history. But he chuckled and added that he never got to see the “end product” after production and delivery. “All your hard work was sent off in a semi down the road. Every day, it started all over again.”

For Dirk Jensen of Grover, who also retired when the factory closed, he recalled 20 years as a field representative to dairy farmers throughout the region. “I was the go-between for the farmers and try to get the farmers to come with us [for milk deliveries]. I just traveled all the time.”

Jensen continued, “There were a lot of good people. These guys are hard workers.”

Among his favorite memories that make him smile was the time the factory needed to be blessed by a rabbi to ensure the factory was kosher. He gave the rabbi a ride to the factory. Trying to make small talk, he asked the rabbi, “Are you ready for Christmas?”

“He gave me a look,” Jensen said, recalling how he realized his faux pas. “He really didn’t want to ride back with me.”

The patient rabbi, however, did bless the Star Valley Cheese Factory.

For Aullman, Turner and Jensen, their memories are mingled with the names of many co-workers and friends who are part of the legacy of the Star Valley Cheese Factory. Some are still alive; some have passed away. Those many names include Frank Dana, Vern Crook, Rex Wolfli, Joshua Floud, DeeLon Merritt, Bruce Turner, Lowell Turner and Floyd Skinner.

The old building is gone now — torn down on the south side of Thayne on Highway 89. The old restaurant and pizza place is gone.

But 20 years after a valley icon closed, the legacy lives on.

- Editor’s note: Undoubtedly, there are myriad names associated with the Star Valley Cheese Factory. Please hop on the comments with the online version of this story and share names and memories.

xx

ed in 1949 by Ernest Brog, the factory made and sold cheese throughout

the United States, as far as Hawaii. COURTESY PHOTO

Let us know what you think!

+1

24

+1

23

+1

+1

+1

+1