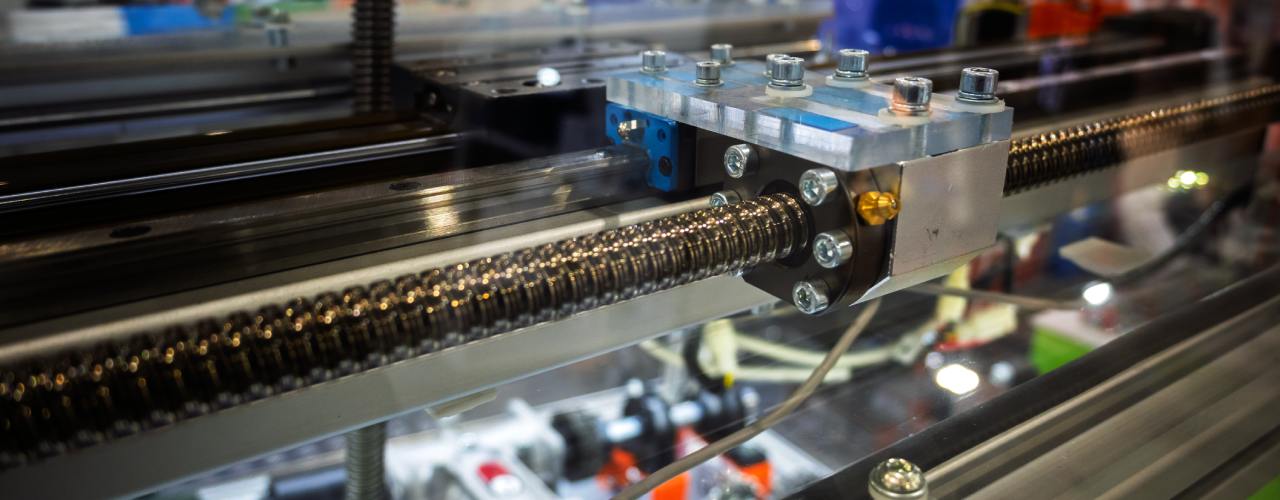

Linear automation systems form the backbone of modern production and manufacturing facilities worldwide. Their performance directly affects output quality, operational speed, and overall system dependability.

To maintain a competitive edge, businesses should consistently evaluate their operational system. These upgrades to elevate the efficiency of your linear automation will unlock new levels of performance and extend the operational life of the equipment.

Adopt Advanced Motion Controllers

Advanced motion controllers provide superior command over motor movement and system synchronization for your machines. These devices execute complex motion profiles with high precision to reduce cycle times and boost productivity. They also support multiple communication protocols for seamless integration into larger factory automation networks.

Upgrades to modern controllers offer sophisticated algorithms that compensate for mechanical imperfections and load variations. This intelligent control minimizes positioning errors and ensures consistent performance under different operational demands.

Integrate High-Resolution Encoders

High-resolution encoders deliver precise feedback about position, speed, and direction for optimal system response. Their fine measurement capabilities enable the motion controller to make minute real-time adjustments. This level of detail dramatically improves the accuracy and repeatability of automated tasks.

The adoption of absolute encoders over incremental ones offers a distinct advantage for system restart. These encoders retain position information after a power loss, which eliminates the need for a homing sequence.

Implement Predictive Maintenance with Smart Sensors

Smart sensors collect continuous data on vibration, temperature, and other vital operational parameters. This information feeds into analytics platforms that predict potential component failures before they can occur. Such a proactive approach to maintenance prevents unexpected stops and expensive emergency repairs.

With reliable linear control troubleshooting tips, you can ensure smooth operation and minimal interruptions. Smart sensors provide the data foundation for a condition-based maintenance schedule tailored to actual equipment use.

Upgrade Lubrication Systems

Automated lubrication systems deliver the precise amount of grease or oil at scheduled intervals. This consistent application ensures all moving parts receive adequate protection against friction and wear. Proper lubrication substantially reduces energy consumption and extends the lifespan of core mechanical components.

An upgrade to a centralized lubrication system simplifies maintenance routines and promotes a cleaner work environment. These systems reduce manual labor requirements and eliminate the common issues of over- or under-lubrication.

Optimize Software and Cable Management

Software optimization is one of the best ways to improve the efficiency of your linear automation and unlock the full potential of your existing hardware. Technicians can refine motion paths and logic to eliminate unnecessary movements and shorten process cycles. Regular software reviews and updates are a cost-effective way to boost overall equipment effectiveness.

Proper cable management and the use of energy chains protect vital connections from wear and damage. This organization prevents signal interference and reduces the risk of cable breakage from repetitive motion.

A series of targeted upgrades can substantially elevate the efficiency and reliability of your linear automation systems. These improvements help reduce downtime, lower operational costs, and increase the productivity of your automated processes.