Achieving precision in manufacturing and quality control depends heavily on the accuracy of your Coordinate Measuring Machine (CMM). A key factor in this process is managing and minimizing measurement uncertainty. For metrology professionals, reducing measurement uncertainty in CMM operations is a constant goal that directly impacts product quality and compliance. This involves a systematic approach that considers the machine, its environment, and operational procedures.

Stabilize the Operating Environment

The environment in which a CMM operates greatly affects measurement results. Temperature fluctuations can cause thermal expansion and contraction in both the workpiece and the CMM structure, which introduces errors. To counter this, maintain a stable, temperature-controlled environment, ideally at 20°C (68°F). Additionally, minimize vibrations from nearby machinery by using isolation pads or placing the CMM in a dedicated, low-traffic area.

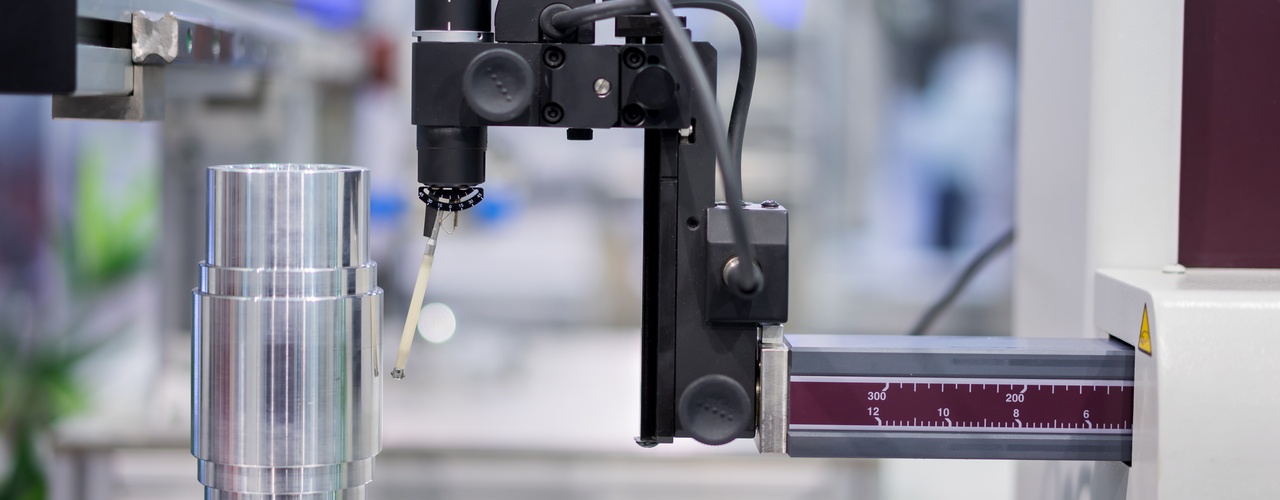

Maintain Probe and Stylus Integrity

The CMM’s probe system is the point of contact with the workpiece, making its condition vital. Styli can wear down or become damaged, leading to inaccurate readings. Regular inspection of the stylus tip for wear or contamination is a simple yet effective step. Furthermore, using the appropriate stylus type and length for the specific measurement task helps prevent errors caused by deflection or improper part access.

Implement Proper Calibration Procedures

Consistent and correct calibration is fundamental to CMM accuracy. This process establishes the machine’s performance baseline and corrects for any geometric errors. Regular calibration of the machine by qualified technicians is necessary. It is also important to use high-quality reference artifacts. Even more essential, knowing when to replace your calibration spheres helps maintain a reliable reference for probe qualification and system checks.

Standardize Operator Technique

The operator’s skill and consistency play a large role in measurement outcomes. Different operators may use slightly different techniques for part alignment or measurement programming. These techniques can introduce variability. Developing standardized work instructions for common measurement routines creates consistency across shifts and operators. Also providing comprehensive training on CMM best practices further empowers your team to produce reliable data.

Daily habits and ongoing professional development are key to finding greater accuracy with your CMM. Reducing measurement uncertainty in CMM operations demands dedication at every level, from the operating environment to individual team members. By making this commitment part of your routine, you can build trust in your results and support the continued success of your quality program.